Process and Preparation

Metal spraying, blasting or thermal spraying is a surface engineering and coating process where a wide range of metals can be sprayed onto the surface of another material.

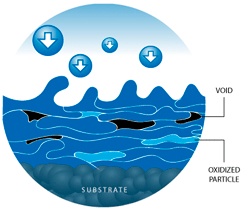

The process involves using specialist technology, equipment and products as well as a method that has been tried, tested and proven over the years. All methods of thermal spraying involve the projection of small particles onto a prepared surface where they adhere and form a continuous coating.

Thermal spraying is widely used to provide on ferrous metals to provide corrosion-protective surface or to change the surface properties, for example improved resistance or more efficient thermal conductivity.

The Basics

To protect any surface and metal, thermal spraying is a very effective method. We use the 28E - Arc Spray System which uses a molten or softened metal to coat the surface, giving it a protective barrier against corrosion and rust or giving it new properties such as anti slip.

A reason to use thermal spraying is the fact that you are able to change the qualities and properties of any surface or material, making them; non-slip, protecting them from corrosion or just simple creating a barrier from scratches. Take a more indepth view into each of these on our other pages.

The Equipment and Materials

Various specialised technologies, equipment and materials are required in order to complete the metal spraying process. These tools are industry grade and proven for efficiency and reliability. The required equipment varies depending on the application and selected product, from spray wire and powder to pipe spraying systems, dust extraction and automated production systems.

Surface Preparation by Gritblasting

Reason for use: Grit blasting is the most commonly used method of preparing surfaces for metal spraying.

Grit blasting is the most commonly used method of preparing surfaces for metal spraying. It removes rust, mill scale and other surface contaminants and produces a suitably roughened surface by projecting a highly concentrated stream of relatively small abrasive particles at high velocity against the surface to be cleaned. It has also been shown to be effective in reducing the loss of fatigue strength.

CONTACT US

Tel 0844 804 6099

info@milesmetallisation.co.uk

ENQUIRE ONLINE

Send us details of your requirements and we will get back to you to discuss a quotation.

OUR WORK

Metal Blasting and Finishes

Non-Slip Metal Surfaces

Anti-Corrosion Coatings

Architectural Steel Work

ADDRESS

Unit 23a, Slough Business Park

94 Farnham Road

Slough

SL1 3FQ

Miles Metallisation Ltd © 2020